# 02

︎

Hexapod

Interior DesignProject Designer

( 2017. Winter-2018. Summer )

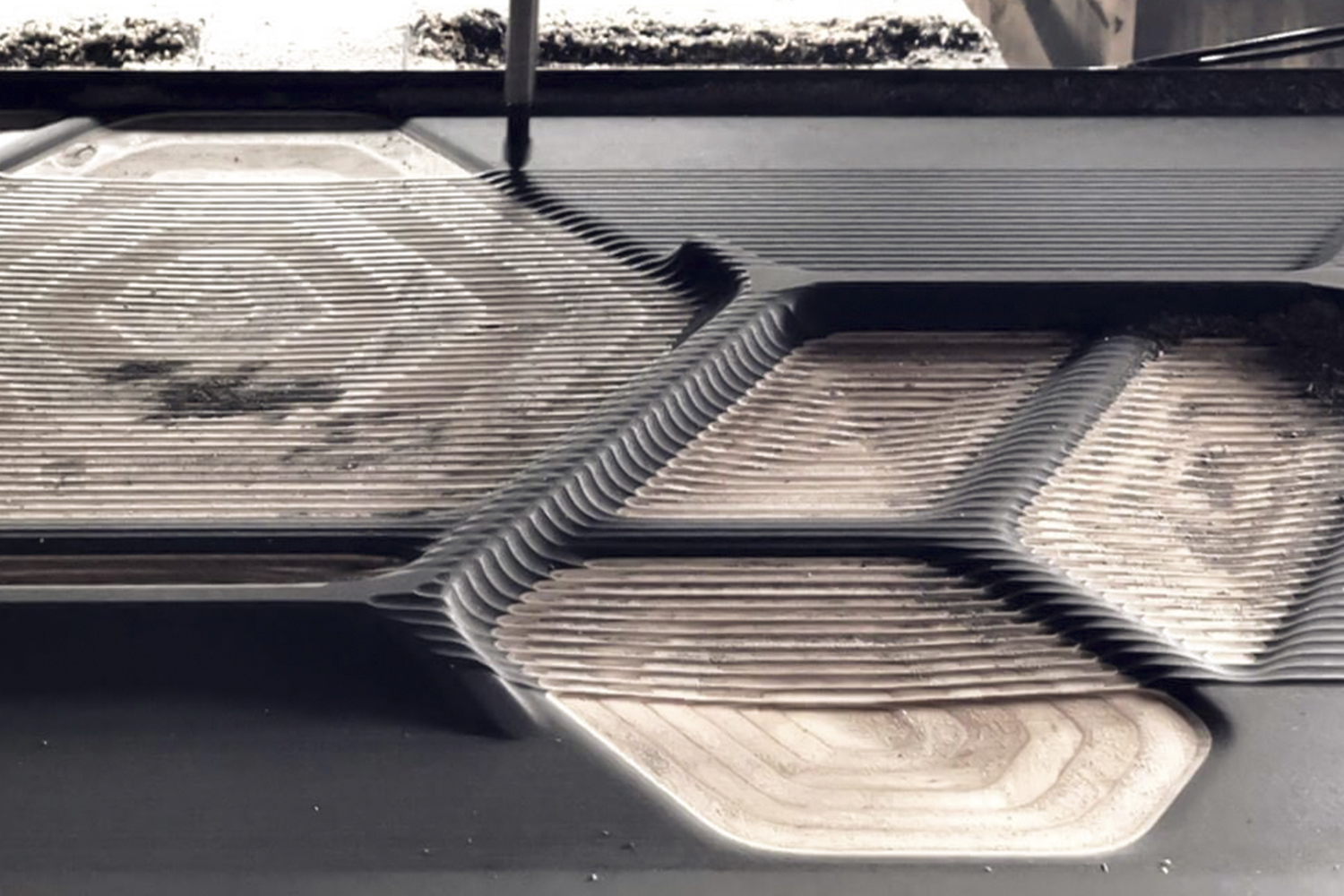

Hexapod, as its name implies, integrates subtractive and additive manufacturing techniques into the wall and bench design through the implementation of a hexagonal module. In the subtractive process, different thicknesses of black Valchromat MDF boards and birch boards were glued together and milled to varying depths through 3 and 6 axis machining methods. Doing so gave interesting wooden-patterns and delicate surfaces. As for the additive manufacturing processes, 3D printed solutions were used to address the need for small-batch custom hardware suited to the dynamics of the designed pattern.

Challenged existing interior design conventions, this design evolved from the integration of material, fabrication, and computational logic. Hexapod design installation brings about a new and unique look and feel for the university space.

published on “Interior” magazine #310, July 2019 ; collaborative with Taiwan Vachromat.

︎ Checking over 30 customed components which were made of CNC/Robotic fabrication.

︎ Checking over 30 customed components which were made of CNC/Robotic fabrication.

︎ The diagram as a contract reference for fabricators and carpenters.

︎ The diagram as a contract reference for fabricators and carpenters.